January 31, 2022

By: PhoenixBizz Staff Writer

PhoenixBizz is a division of Sofvue, LLC

Printed with permission of Data Titan and Sofvue LLC

RFID (Radio Frequency Identification) tags are smart labels that allow you to store a wide range of information, such as serial numbers and a short description. RFID enables organizations to use this information to improve efficiency and accuracy in their supply chain.

RFID serves a similar purpose to that of a barcode, where data is captured by a device and stored in the database. However, unlike barcode scanners, RFID readers don’t need to be placed near the product and can “read” information without direct line of sight. RFID also allows you to scan more items simultaneously, thereby saving time and energy.

How Does RFID Work?

Now that you have a little detail about what RFID is, let’s understand how it works.

RFID is powered by AIDC (Automatic Identification and Data Capture) technology. It can automatically identify objects, collect data about them, and enter the same into your system with little to no manual intervention.

RFID compromises an integrated circuit and an antenna that transmits data to the RFID reader. Let’s understand the components of RFID in depth.

RFID Tag

It is attached to the physical product, and it is comprised of two parts:

◾Integrated circuit: used for storing and processing the information

◾Antenna: used to receive and transmit signals

RFID tags also include non-volatile memory storage that consists of programmable or fixed logic for sensor data and transmission.

It is also worth mentioning that there are three types of RFID tags.

◾Passive: Uses the reader’s signal energy to turn on the tag and has no battery.

◾Active: It consists of a battery that transmits signals periodically. They can send signals as far as 100 meters.

◾Battery-assisted Passive: This type of RFID device contains a battery but don’t transmit signals regularly like the active RFID tags.

RFID Reader

RFID reader consists of a transceiver and a two-way radio transmission receiver.

The transceiver emits an encoded signal to activate the RFID tag. The tag transponder then converts the radio signal into usable power while responding to the reader.

How Can You Incorporate RFID Into Your Supply Chain?

RFID caters to all three critical aspects of the supply chain, including.

#1 Integration

Better integration is crucial for the success of the supply chain. RFID tags enable businesses to capture data for goods in transit and share the same data with employees or company partners.

#2 Operations

RFID scanners allow companies to monitor the movement of goods on a daily basis, especially in large warehouse facilities where semi-tractor trailers are continuously loading and unloading at multiple bays. With real-time information about warehouse activities, businesses can manage inventory with far less complexity.

#3 Distribution

Logistics is all about moving products from one place to another quickly, and with little or no errors. RFID allows you to use real-time technology and software to know the actual location of individual shipments, as well as determine how much time remains before the shipment will reach its intended destination. With this type of information at your fingertips, literally, you can better manage your inventory, communicate more effectively with your team, and most importantly, communicate logistics in near real-time with your distribution partners.

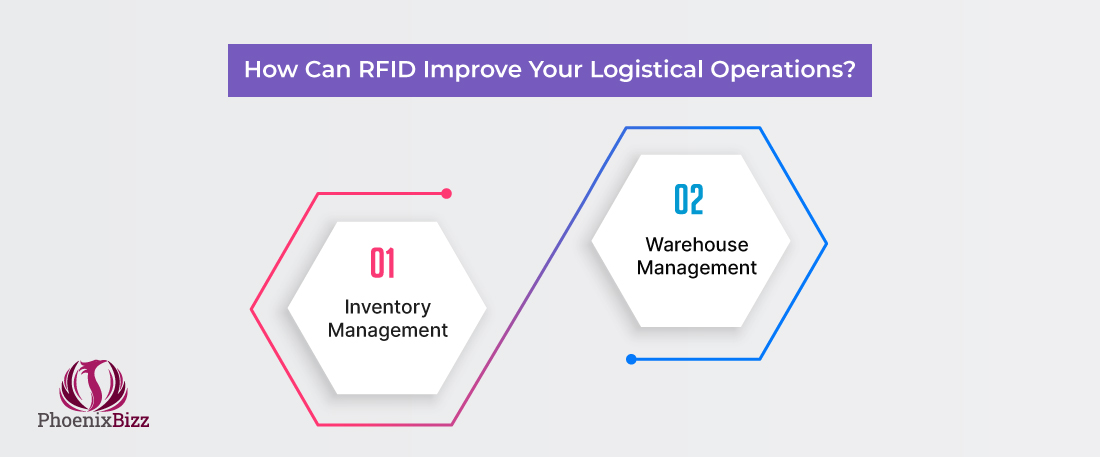

How Can RFID Improve Your Logistical Operations?

Now that you know the application of RFID in logistics, let’s understand how it can improve your operations.

#1 Inventory Management

Inventory management includes monitoring, controlling, and storing materials, parts, or products scheduled for delivery. Inaccuracies in inventory can lead to both monetary and business loss.

However, with RFID, you can streamline inventory management. You can scan multiple items at a time. You can also get real-time visibility over semi-finished materials and in-stock raw materials. This will help reduce manual errors and improve inventory accuracy.

#2 Warehouse Management

A warehouse is where you store products received from different suppliers. Those products are then shipped across the country, to other logistic centers, wholesalers, manufactures, D2c’s, and retailers.

RFID can also support warehouse management and improve your overall processes. For instance, you can automate important tasks, such as the identification and validation of products. This provides you with better visibility of your warehouse while reducing labor costs.

Read this blog: The Growth of Direct to Consumer (D2c) Marketplace and Why It’s Growing

Why Should You Use RFID In Your Logistics Operations?

There are several reasons to invest in RFID in your logistics business. Here are a few.

#1 Improved Visibility

Eliminate the worries about misplaced items in the warehouse or during transit using RFID. This also helps resolve issues that result from improperly trained employees, human oversight, and mistakes made during manual processes.

#2 Reduced Labor Costs

RFID can automate various aspects of the supply chain and logistic cycle. Apart from tracking the items from anywhere, drivers can complete the weighing process by simply holding their RFID tag next to the readers to get a printed ticket in return. This saves time and money in the long run, and it often carry’s a profitability boost.

#3 Minimize Thefts

As we’ve already discussed, RFID allows you to track the movement of every shipment. You can, in fact, gain quick and remote access to the product’s location, mitigating the risk of theft.

#4 Enhanced Productivity

Since employees no longer need to manually find products, they can use their valuable time on other value-add tasks. They can focus more on loading products to trucks, delivery vehicles, shipping freighters and rail cars, helping to ensure deliveries are managed and completed as soon as possible. Also, RFID minimizes the risk of recalls and reduces the instances of incorrect distribution.

Read RFID Tags Through a Mobile App

Incorporating RFID in your logistics and supply chain to read the tags via a smart device or mobile phone was science fiction twenty years ago, but much has changed, especially since the start of the global pandemic and the strain placed on supply chains across the globe. If you are interested in hiring a mobile application (app) company with the right team of experts to develop a solution that suits your company’s specific needs, contact Phoenix Bizz. We have a team of seasoned, professional and knowledgeable application developers who know how to get things done. Our mid-level app developers have an average of 8 years’ experience, and our lead architect has 20+ years of experience. Give us a call at 623-845-2747 to learn more about our services, and how we can serve your business’ growth.