January 28, 2025

By: PhoenixBizz Staff Writer

PhoenixBizz is a division of Sofvue, LLC

Printed with permission of Data Titan and Sofvue LLC

The logistics of the supply chain are a critical component of operations, a fact well understood by nearly all companies in the sector. However, with the evolving global landscape and persistent disruptions, managing supply chains has grown increasingly intricate. Fortunately, advancements in artificial intelligence (AI) and the Internet of Things (IoT) have shown significant gains to alleviate the challenges faced by supply chain managers.

Data obtained from Markets and Markets suggests that AI in the Supply Chain market will be worth $40.53 Billion by 2030. The report also indicates that companies that deploy AI strategies will be able to gather and use precise data yielding better predictive analytics to enable organizations to act proactively and reduce potential interruptions.

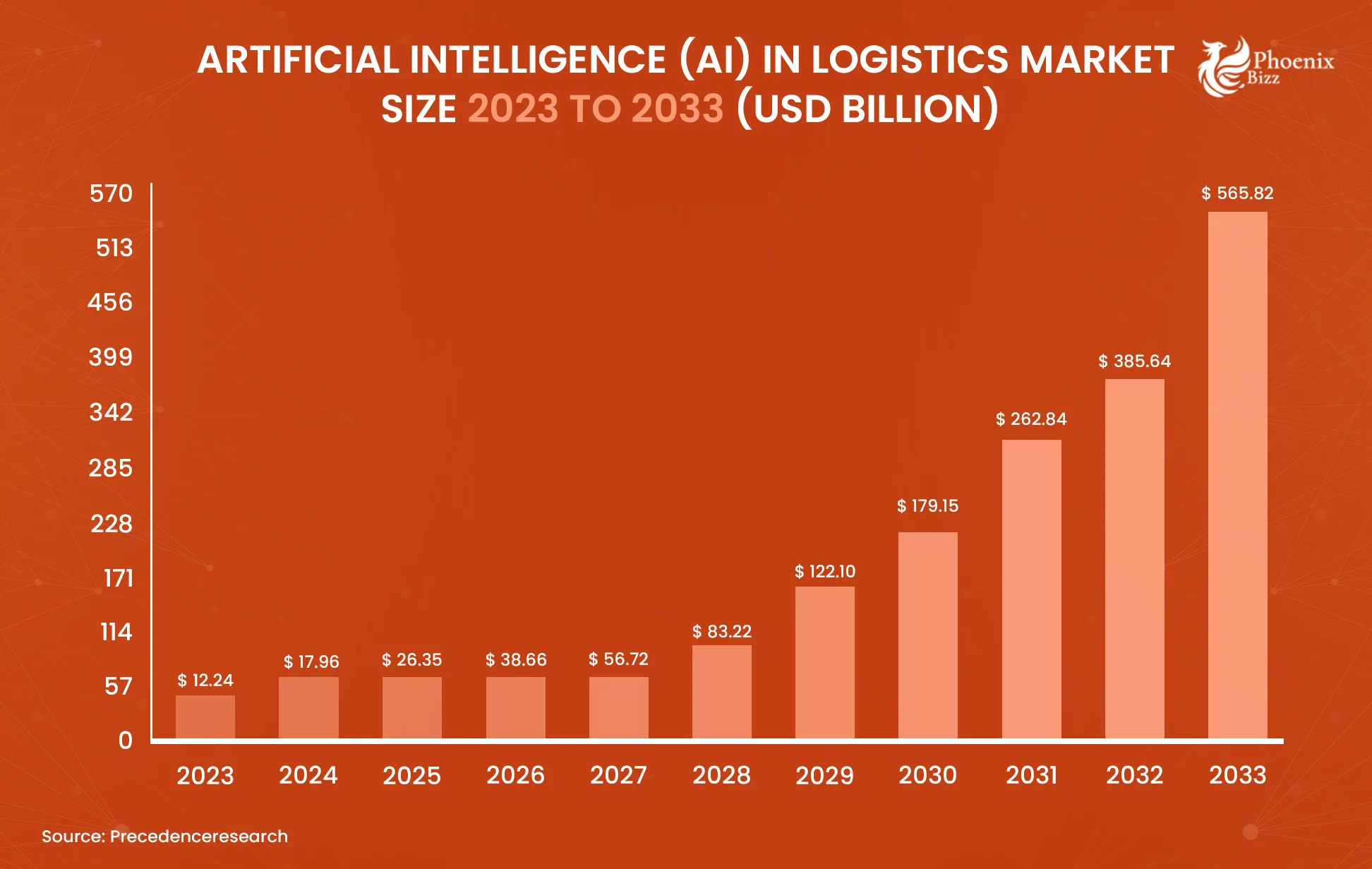

The primary aim of introducing AI in the supply chain and logistics is to attain desirable results with increased productivity. The global expansion of AI in the Logistics market will rise to around $565.82 billion by 2033, with most of this growth the result of AI advancements.

Let's explore in greater detail how AI is revolutionizing supply chain management, focusing on the ways its various subsets increase efficiency. We'll examine prominent case studies that showcase real-world applications, providing valuable insights to help you seamlessly integrate AI into your operations and synchronize your workforce, machinery, and software for maximum effectiveness.

Uses of Data Analytics in Supply Chain Management?

Accelerating supply chain management demands precision and foresight. By leveraging data analytics, organizations can process and analyze vast amounts of data, enabling companies to streamline operations, reduce risks, and optimize production processes. Data analytics acts as a critical enabler, ensuring that production activities are well-supported with adequate materials and timely decision-making to maintain a fast-paced workflow.

Companies that effectively utilize supply chain data analytics can significantly enhance their business in five critical areas, or what we call the (5A) strategy:

1. Alignment

Data analytics, when combined with IoT devices, offers unparalleled insights through machine-generated data analysis. This alignment of technology and analytics enables real-time monitoring and management, ensuring every aspect of the supply chain operates in harmony.

2. Accuracy

The integration of advanced analytics tools provides businesses with intelligent, result-driven predictions. By analyzing historical data and current trends, companies can make more informed decisions, minimizing errors and better aligning outputs with strategic objectives.

3. Association

One of the most impactful benefits of data analytics is its ability to connect operational teams and devices seamlessly. This enhanced connectivity fosters collaboration, streamlines workflows, and improves overall productivity, creating a unified network that drives better decision-making.

4. Agility

Data analytics equips supply chains with the agility needed to adapt to changing market conditions and unexpected disruptions. By quickly analyzing new information and providing actionable insights, businesses can pivot strategies, implement contingency plans, and stay competitive even in volatile environments. This agility fosters resilience, a critical trait for supply chains in today’s fast-paced global markets.

5. Automation

Driven by AI and data analytics, automating processes takes routine and repetitive tasks off human hands, allowing teams to focus on higher-value activities. Predictive maintenance, automated order processing, and real-time inventory updates are examples of how automation enhances supply chain efficiency. These automated processes not only improve accuracy but also reduce costs, minimize human error, and speed up overall operations.

AI further amplifies these capabilities by its ability to analyze massive datasets, uncover complex relationships, and provide comprehensive operational visibility. Through AI-driven insights, businesses can elevate their decision-making processes, adapt to changes swiftly, and gain a competitive edge.

However, the successful adoption of these technologies often goes well beyond their technical capabilities. To fully harness AI’s transformative potential, organizations must also invest in structural and cultural changes. This includes fostering a data-driven mindset, enhancing cross-functional collaboration, and aligning technological initiatives with strategic business goals. By combining technology with thoughtful organizational measures, companies can unlock the full potential of AI and data analytics to modernize their supply chain management.

You may also like to read: How Smart Warehouses and Mobile Apps Are Being Transformed by AI in Logistics

Different AI-based Data Analytics Used in Supply Chain Management & Logistics

The implementation of AI is a transformative force for the industry, offering unprecedented opportunities for growth and innovation. AI-powered data analytics provides sophisticated and versatile models tailored to address a wide range of challenges and applications, making it an invaluable asset for modern businesses.

● Predictive Analytics

Using analytical models to estimate demand, anticipate threats, and determine supply times is known as predictive analytics. The solution helps businesses predict issues and steer clear of crucial decision situations by combining historical and real-time data.

● Prescriptive Analytics

The goal of prescriptive analytics is to suggest potential courses of action. It uses optimization algorithms and simulation models for efficiency by looking at what it believes to be the ideal routes, how inventory management should be carried out, and other ways to improve the supply chain, and where needed, the cold chain.

● Descriptive Analytics

Enterprises can analyze the past supply chain performance to make better decisions for present projects. Using AI helps in making potential improvements, optimizing supply chain management.

Refining Your Supply Chain and Logistics Operations with AI

As mentioned earlier, businesses focusing on planned use of AI in supply chain and logistics enjoy countless benefits. They have more streamlined operations, timely deliveries, reduced machine downtimes, and more. Here are some more benefits:

1️⃣ Simplified Warehouse Operations

Tasks like sorting and tracking goods can be automated with the help of AI. This reduces manual work, allowing the company to utilize their workforce in other important tasks like delivery, quality checks, etc.

2️⃣ Informed Decisions

Decision making is an integral part of supply chain management. The amount of raw material required, delivery schedules, workforce requirements, etc. are decided based on the company’s needs. With the help of AI, supply chain managers can make concrete decisions solely influenced by information.

3️⃣ Reduced Waste

AI uses the available production data to detect problems, reduce waste, and predict unnecessary production. Inventory planning with the help of machine learning models shows the exact proportions of materials needed for making products, reducing overall resources needed in the supply chain process.

4️⃣ 24x7 Inventory Tracking

Smart Internet of Things (IoT) applications give an actual picture of stock status and whereabouts. Stock alerts for either stock outs or overstocks minimize the disruption of the supply chain and enhance inventory control. Any discrepancy in the stock is automatically and instantly detected, allowing you to decide quick resolution.

5️⃣ Demand Forecasting

AI models leverage historical data and current market trends to generate predictive forecasts. By optimizing production and inventory schedules in advance, businesses can minimize instances of overproduction or stockouts, ensuring that the supply chain remains closely aligned with demand. This synchronization enhances efficiency and reduces waste, creating a more responsive and cost-effective supply chain.

6️⃣ Rapid Delivery

Monitoring route planning and traffic conditions using AI helps save time for routes and deliveries. Logistics planning is improved through the predictive analytical approach leading to removal of prior delays, eventually improving customer satisfaction.

Steps To Use AI and Data Analytics in Supply Chain

Let us now have a close look at the basic steps of how AI and data analytics are integrated into supply chain management. Most AI software development companies follow the below-mentioned process:

Step 1. Hire A Software Developer

By hiring a professional Artificial Intelligence (AI) software development company, you can outsource your logistics and supply chain demands to a software development firm capable of understanding and developing the right solution. This allows experts to work on your logistics management software, while you focus on other essential tasks.

Step 2. Discovery

The first step is to establish clear objectives for incorporating AI and data analytics into your manufacturing or supply chain strategy. Defining these goals ensures your service provider can design a targeted and effective project roadmap. Key focus areas, such as inventory optimization, route selection, and risk management, are identified during this phase to align with your business priorities.

Step 3. Data Gathering

A dedicated team collects critical information from various parts of your supply chain, including historical reports, inventory records, employee details, and order data. Since much of this raw data may be inconsistent or incomplete, it undergoes a process known as data cleaning. This involves addressing duplicate entries, filling in missing information, and correcting formatting errors to create a reliable and usable dataset.

Step 4. Building AI Algorithms

The next step is to select AI algorithms that address specific challenges within your supply chain operations. These algorithms are chosen based on the goals defined during the discovery phase. Cutting-edge AI technologies, including robotics, natural language processing (NLP), predictive analytics, and machine learning, are commonly employed to improve efficiency, accuracy, and decision-making in supply chain management.

Step 5. Integration With the System

Once the appropriate technologies and algorithms are identified, they are integrated into your supply chain management system. This step involves linking all components of your infrastructure to the AI models and migrating data to the new AI-driven software. Seamless integration ensures that the entire supply chain ecosystem operates cohesively with the newly implemented technology.

Step 6. Pilot Testing

Before full-scale deployment, pilot tests are conducted to evaluate the performance of the AI algorithms in a controlled environment. This involves implementing the technology on a smaller scale to identify and resolve any issues or bottlenecks. Pilot testing provides critical insights, enabling developers to refine the system and ensure it functions optimally when applied across the entire supply chain.

Step 7. Revisions

Based on the findings from pilot testing, revisions are made to fine-tune the software and address any identified shortcomings. Additional tests may be conducted to confirm the effectiveness of these updates. Once the revisions are complete, your supply chain management system is ready for full deployment, offering enhanced accuracy, productivity, and efficiency tailored to your business needs.

AI In Supply Chain Management Case Studies

Now is unparalleled time in history for supply chain and logistics enterprises to transition to sophisticated, technology-driven management systems. Data-centric platforms and advanced AI-integrated software have already proven themselves in the marketplace and are able to surpass operational benchmarks and achieve strategic objectives like no other time in the past, underscoring their transformative potential within the industry. Here’s a few case studies to drive the point home:

BMW

The renowned automobile manufacturer BMW is celebrated for its ability to customize vehicles to align with buyers’ preferences and aspirations. Leveraging NVIDIA’s Omniverse Enterprise, BMW created a digital twin of its factory, enabling real-time simulations and seamless collaboration. By integrating diverse systems and GPUs, they connected tools like Autodesk’s Revit and Dassault Systèmes’ CATIA (Computer-Aided Three-Dimensional Interactive Application), allowing design teams to work simultaneously within a shared digital environment. To ensure compatibility across the platform, materials were reformatted into the USD (Universal Scene Description) format.

Additionally, BMW utilized NVIDIA Isaac Sim for its delivery robots, enabling them to train with synthetic data across various scenarios, enhancing their performance. This innovative use of artificial intelligence significantly boosted productivity, reduced errors, and advanced the efficiency of BMW's supply chain and manufacturing processes, underscoring the transformative potential of AI-driven solutions.

IBM

IBM sought to harness the power of artificial intelligence and develop a robust cognitive supply chain capable of driving cost reduction and enhancing productivity. To achieve this, they implemented an integrated stack of solutions that leveraged data across various stages of the supply chain. This innovative architecture included key technologies such as IBM Edge Application Manager, IBM Maximo Visual Inspection, and IBM Track and Trace IoT.

The cognitive supply chain approach provided IBM with real-time, accurate visibility into supply chain operations. This capability enabled stakeholders and managers to respond swiftly to changing demands and mitigate delays. By dynamically re-sourcing and re-routing parts as necessary, the company successfully maintained operational continuity and fulfilled 100% of orders, even amid the disruptions caused by the pandemic. This transformative use of AI underscored IBM's ability to adapt to complex challenges and optimize supply chain performance under adverse conditions.

2025 Trends in AI In Supply Chain

#1. Generative Artificial Intelligence & AI Bots

Route optimization is one of the key aspects of supply chain management. Gen AI is actively being integrated into mobile applications to help drivers find faster routes, minimizing delayed deliveries. Another area where gen AI is gaining popularity in 2025 is customer management and automated tasking. AI bots are increasingly used in factories and supply chain management warehouses to assist humans with multiple tasks.

#2. Value Realization From AI

AI is reshaping supply chain networks with unparalleled creativity and efficiency. While traditional AI has been enhancing processes for years, generative AI introduces transformative opportunities by enabling smarter solutions and reducing redundancy. For this potential to be fully realized, organizational leaders must cultivate trust in AI-driven decision-making, which combines the power of data with informed intuition.

Leadership, commitment to analytics, and proper governance are essential to leveraging AI as a strategic business tool. By using AI to identify opportunities beyond the constraints of traditional economic thinking, organizations can unlock the full potential of the modern industry. This approach supports the sustainable growth of supply chains, fostering resilience and innovation in an increasingly complex global landscape.

Automate Your Supply Chain with PhoenixBizz

The advantages of artificial intelligence in supply chain management are profound and increasingly indispensable. As the adoption of this transformative technology continues to expand, it is imperative for companies within the industry to prioritize the integration of AI into their supply chain systems. Doing so enables enhanced efficiency, agility, and resilience in an ever-evolving market landscape.

Creating a strategic alliance with PhoenixBizz to future-proof your business through our advanced AI and data analytics services is a smart choice. We are an award-winning and trusted AI software development company having served countless businesses across the nation in achieving their business goals. Past clients include the USAF, NYSE, Edvance Research, the University of Texas at San Antonio, International Insurance Group (IIG) and hundreds of small businesses. Our solutions are designed with a focus on quality, scalability, and innovation, leveraging cutting-edge technologies to drive sustainable growth and performance. To learn more, contact us at 623-845-2747.

RE: 11880

Citations

Markets and Markets: https://www.marketsandmarkets.com/Market-Reports/ai-in-supply-chain-market-114588383.html

Precedence Research: https://www.precedenceresearch.com/artificial-intelligence-in-logistics-market

IBM: https://www.ibm.com/case-studies/ibm-supply-chain?