December 02, 2024

By: PhoenixBizz Staff Writer

PhoenixBizz is a division of Sofvue, LLC

Printed with permission of Data Titan and Sofvue LLC

Generative Artificial Intelligence (Gen AI) is revolutionizing industries worldwide. From powering next-generation mobile apps to enhancing communication with unprecedented efficiency, Gen AI is rapidly reshaping how we interact and innovate. Even traditional factories are evolving into cutting-edge operations, leveraging the capabilities of advanced technologies to modernize and optimize their processes.

According to Markets and Markets, the smart factory market size is projected to reach an impressive $164 billion by 2029. These staggering figures underscore the growing popularity and adoption of smart factories. By combining the power of Large Language Models (LLMs) and mobile apps, businesses are implementing transformative strategies to enhance efficiency and innovation. This approach, including the use of a custom mobile app development company like Phoenix Bizz, ensures that companies can design and deploy tailored solutions to optimize factory operations, streamline workflows, and drive scalability in this rapidly expanding market.

What Are Smart Factories?

Manufacturing businesses are increasingly embracing the smart factory model, creating an interconnected ecosystem of devices and machinery powered by advanced technology. This approach integrates logistics and manufacturing processes through software and mobile applications, revolutionizing traditional operations.

Smart factories set new standards for productivity and efficiency, leveraging automation, data-driven decision-making, and cutting-edge digital tools. Key enablers of this transformation include Large Language Models (LLMs) and mobile apps, which facilitate real-time data processing and enable faster, more informed decision-making. This enhances operational agility and drives significant improvements across manufacturing environments.

The rise of smart factories stems from the limitations of traditional operations, such as:

Step#1 Time inefficiency

Manual processes were slow and required extra time to complete tasks.

Step#2 High operational costs

Traditional setups relied on extensive staffing to manage various functions.

Step#3 Communication challenges

A lack of proper communication tools often led to miscommunication and reduced transparency between teams and departments.

By addressing these challenges, smart factories are reshaping the future of manufacturing.

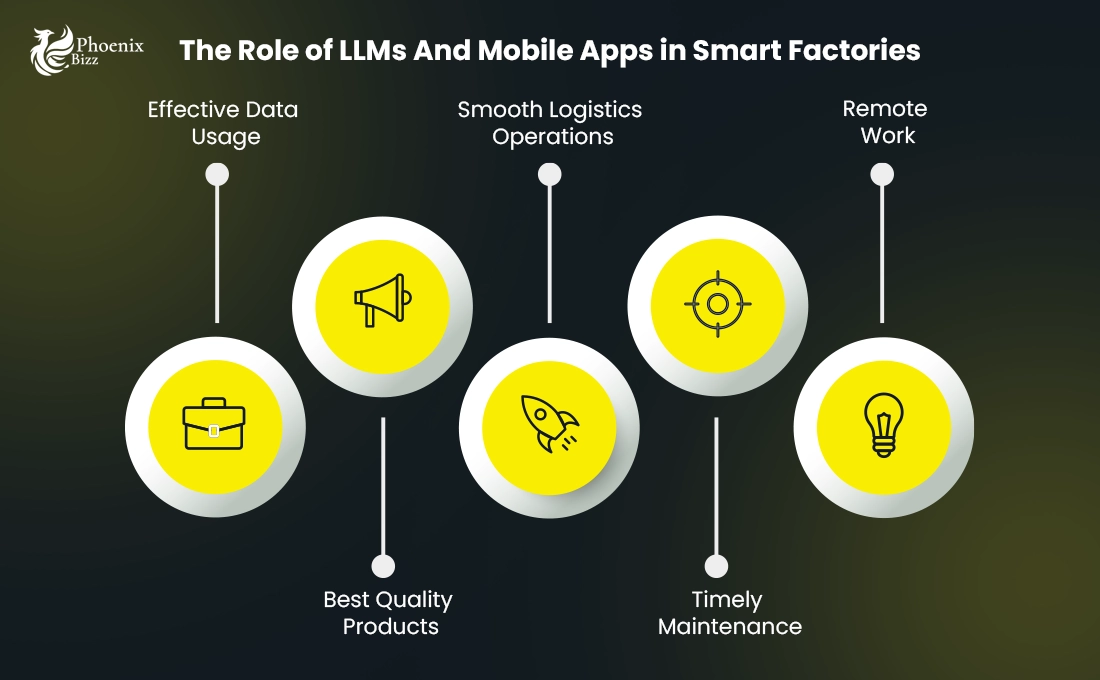

The Role of LLMs And Mobile Apps in Smart Factories

Software developers, engineers and programmers often design mobile apps integrated with Large Language Models to bring quick results and make factory operations effortless. LLMs play a key role in transforming traditional factories into smart factories. From automatically aligning daily tasks to providing deep analysis of the factory’s operations and logistics management, LLM-driven mobile apps provide ease to factory staff.

1️⃣ Effective Data Usage

Mobile applications developed utilizing LLM are valuable tools in creating smart factories. They can process massive amounts of manufacturing data to facilitate efficiency and innovation. These apps apply machine learning techniques to estimate when maintenance is required for the equipment, when and how to schedule production, and to identify errors and downtime. With historical and live data LLMs help factory managers make appropriate decisions, minimize time losses, and increase manufacturing efficiency, creating an environment of a real-time smart factory.

The integration of Large Language Models (LLMs) into mobile applications is a significant change for smart factory operations, offering transformative potential for manufacturing efficiency and innovation. Beyond traditional data processing, LLM-powered applications enable predictive analytics and adaptive decision-making by leveraging historical and real-time data. These tools are instrumental in predictive maintenance, ensuring machinery runs smoothly and reducing unexpected downtime. They also optimize production schedules by analyzing patterns and demand forecasts, helping factories allocate resources more effectively.

Moreover, these applications enhance quality control by identifying anomalies in processes or output, ensuring that potential issues are addressed proactively before they escalate into costly problems. By combining live data streams with historical performance metrics, LLMs create a feedback loop that continuously refines factory operations, making them more responsive to dynamic demands and challenges.

Additionally, mobile apps driven by LLMs are democratizing access to smart factory tools. Factory managers and technicians can receive critical information directly from their smart devices, enabling on-the-go decision-making and collaboration. This accessibility fosters a more agile manufacturing environment where teams can respond to challenges in real-time, supported by accurate and actionable insights.

2️⃣ Best Quality Products

Whether your factory manufactures automobile parts or is involved with time-centric food packaging and processing, quality stays paramount. Manufacturing low-quality products can tarnish your factory’s reputation. Manually monitoring the quality is challenging and time-consuming. However, with LLM mobile apps, you can closely monitor the quality of the items being manufactured in your smart factory.

The advanced system integrated into these mobile apps rejects all poor-quality products. This also gives you reliable information on areas of improvement so your team can reduce production downtime.

3️⃣ Smooth Logistics Operations

LLM mobile applications give insight into the logistics of smart factories. For example, maintenance and inventory. These applications rely on big language models to analyze logistic data, detect possible delays, and suggest the best route to follow. With instant access to changes in inventory and supply chain status, it becomes easy to track bottlenecks. This also increases productivity, which is crucial for any smart factory.

4️⃣ Timely Maintenance

LLM mobile apps are connected to all the machines and systems of the factory. They keep track of the equipment condition and automatically schedule maintenance whenever due. This ensures that all factory machinery and tools remain in the best condition, avoiding unnecessary delays. Timely repair and maintenance service also prioritizes the safety of factory workers, reducing the chances of accidents.

5️⃣ Remote Work

Since LLM mobile apps are accessed on smartphones, factory managers can monitor the operations from anywhere. Whether they are stuck in traffic or stuck at home due to a flood or snow, they can keep a close watch on operations through the mobile app. It is amazing how a simple application controls numerous functions of the factory while also providing real-time data.

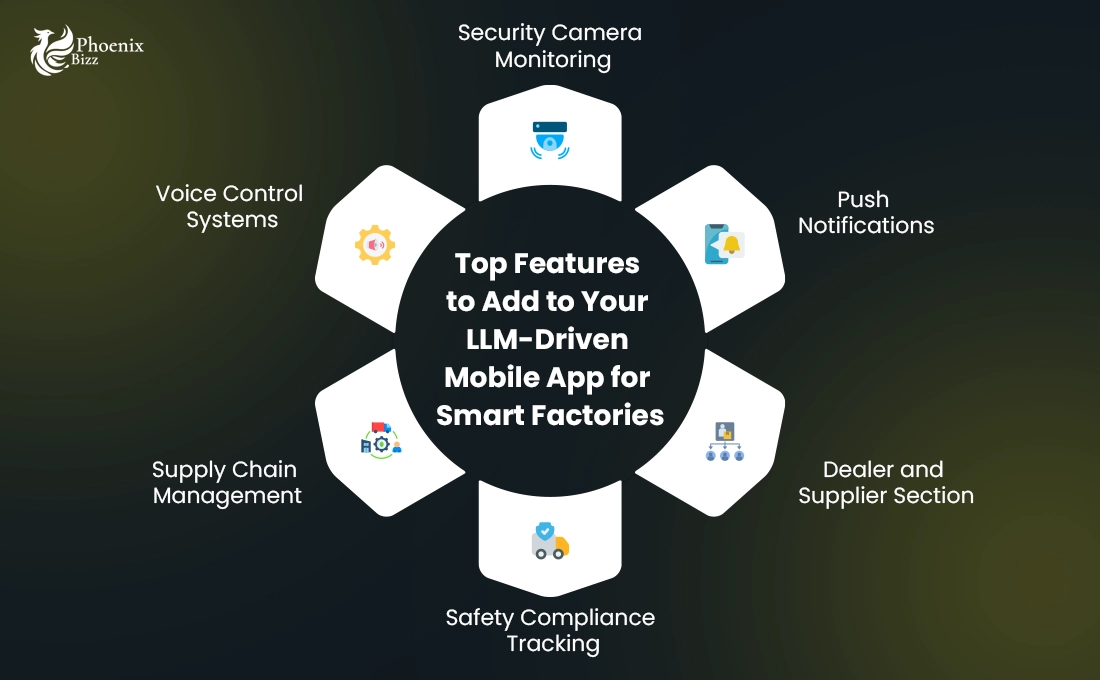

Top Features to Add to Your LLM-Driven Mobile App for Smart Factories

A mobile app can only be successful when integrated with the right and useful features. If you are planning to get an LLM-powered mobile app for your smart factory, do not forget to add the following features:

✔️ Security Camera Monitoring

Factories store millions of dollars' worth of raw materials, finished goods, and work-in-progress inventory. These valuable items attract thieves, which can lead to a major loss for the factory owners. By directly connecting the security cameras to the LLM-powered mobile app, guards can monitor the factory premises around the clock.

✔️ Push Notifications

Timely alerts can be sent to the factory manager, owner, suppliers, and other stakeholders about vital details and operations. This feature ensures that everybody remains on the same page, eliminating confusion. Maintaining proper communication and transparency is key to a successful business. Adding a push notification feature adds value to your smart factory by enabling a smooth information flow.

✔️ Dealer and Supplier Section

The app can include a dedicated tab for dealer and supplier management, streamlining workplace organization. This feature facilitates the ordering of materials and tracking shipments to ensure the timely availability of essential supplies. By fostering a well-structured approach to managing dealers and suppliers, the system strengthens relationships and promotes a smooth and efficient manufacturing process.

✔️ Safety Compliance Tracking

Safety compliance is necessary for the smooth functioning of a factory. Any loophole in safety maintenance can lead to license cancellation and fines. The mobile app, when integrated with a safety compliance tracking system, helps with the following:

✅ Timely detection of unsafe machinery

✅ Equipment in need of urgent maintenance

✅ Loopholes in the fire detection system

✔️ Supply Chain Management

A separate feature to track the supply chains of the factory is a must-have. It ensures that production is never disrupted. Supply chain tracking integrated into the mobile app assists in monitoring inventory and tracking of materials in transit and logistics. This feature offers the much-needed monitoring of the supply chain activity with enhanced productivity and no supply depletion. It allows smooth operations and leads to timely completion of work being performed on production lines.

✔️ Voice Control Systems

Voice control systems enable the factory operators to control machinery and the systems through voice commands, hence enhancing efficiency due to limited hand control. Voice command control system allows operators to accomplish a task or get information without touching the device which can be extremely useful in a busy production setting.

Real LLM-Powered Smart Factories in the US using Mobile App Technology

Here are four actual LLM powered smart factories in the United state that have migrated mobile applications into their daily operations:

Ford Motor Company's River Rouge Complex

Dearborn, Michigan

Ford has integrated mobile applications into its manufacturing processes, allowing employees to monitor production lines, manage inventory, and perform quality checks in real-time. This mobile integration enhances operational efficiency and responsiveness.

General Electric's Brilliant Factory

Greenville, South Carolina

GE's Brilliant Factory leverages mobile applications to provide workers with real-time data on machine performance, maintenance schedules, and production metrics. This connectivity enables proactive maintenance and swift decision-making on the factory floor.

Boeing's Everett Factory

Everett, Washington

Boeing employs mobile applications to streamline assembly processes, allowing technicians to access digital work instructions, report issues, and track parts using handheld devices. This approach reduces errors and improves assembly efficiency.

Caterpillar's East Peoria Facility

East Peoria, Illinois

Caterpillar utilizes mobile applications to monitor equipment health, track production metrics, and facilitate communication among team members. This mobile strategy enhances equipment uptime and overall productivity.

Conclusion

With industries rapidly evolving, manufacturers are continually looking for ways to streamline operations. Smart factories offer optimized operational workflows, often benefiting the business. Factory owners can benefit further by adopting LLM-powered mobile apps that offer countless benefits.

You can rely on PhoenixBizz, an award winning and leading mobile app development company, for your software-related requirements. Our team is proficient in delivering powerful LLM-driven mobile apps for smart factories.

A division of Sofvue LLC, we have served the marketplace for two decades, with hundreds of clients, hundreds of projects and too many users to count. We can help you with innovative mobile apps, websites, web apps, and more. Feel free to contact our support team at 623-845-2747 to discuss your next LLM and mobile app project.

You may also like to read: How Smart Warehouses and Mobile Apps Are Being Transformed by AI in Logistics

RE: 11844

Citations:

Markets and Markets: https://www.marketsandmarkets.com/Market-Reports/smart-factory-market-1227.html